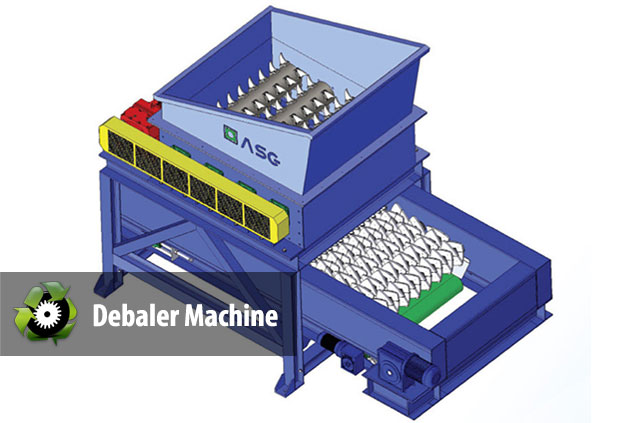

Product Description

The debaler, while not required, is the first piece of machinery in our standard PE film washing line. Generally, PE film will arrive at washing plants in large bales, compacted bundles of LDPE / LLDPE film tied together by metal wires. In order for the plastic film to enter the washing line, these bales must first be “busted” so the film can flow freely onto the conveyor belts.

The debaler, while not required, is the first piece of machinery in our standard PE film washing line. Generally, PE film will arrive at washing plants in large bales, compacted bundles of LDPE / LLDPE film tied together by metal wires. In order for the plastic film to enter the washing line, these bales must first be “busted” so the film can flow freely onto the conveyor belts.

If a debaler machine is not used, the bales of plastic film must be manually opened and placed onto the conveyor which increase the number of people operating the washing line. While the addition of 1-2 people is fine for countries where labor is relatively cheap, for countries where manual costs is a concern, we highly recommend taking advantage of the debaler.

Instead of manually opening the film bales, bales can just be dropped into the debaler’s vertical feeder where slow moving hooks grapple and breaks the wires used tie the bales together.

Specifications

| Feeder Dimensions: | 1450mm x 1650mm |

| Main Motor Power: | 5.5 KW |

| Conveyor Motor Power: | 7.5 KW |

More Images

Ordering

Our lead time for single pieces of equipment is 30 days from the signing of purchase contract. For custom orders such as complete washing lines, the lead time is between 60 – 90 days. Actual lead times will depend on the project’s complexity as well as our factory’s availability.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.