Product Description

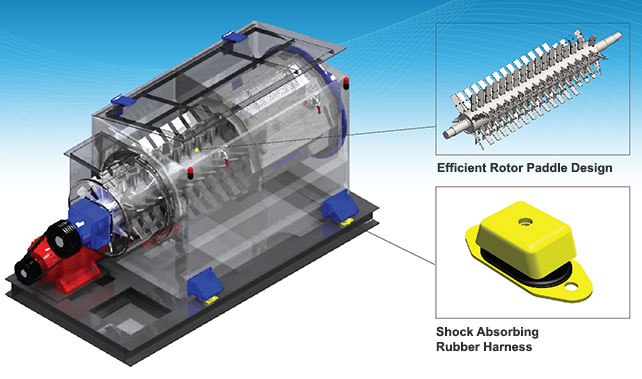

The first drying stage of our standard PP / PE film washing line, the dewatering machine can efficiently remove large portions of moisture from the PP / PE film directly after the washing process. Strategically placed after the sink / float separation tank, the dewatering machine uses centrifugal force to spin water outwards while the PP / PE films are contained within.

At the center of the dewatering machine is a long shaft mounted with many paddles spun to nearly 1,000 rotations per minute by an electric motor. Surrounding the paddled shaft is a mesh screen tunnel. As the slurry PP / PE film is fed into the vertical feeder, its instantly thrown outwards against a mesh screen that surrounds the shaft. Water passes through the mesh screen and is collected for recycling while the PP / PE film is continuously thrown and mixed around inside.

The PP / PE film, now partially dried, moves onto the next drying equipment, usually a thermal drying system. Generally, the PP / PE film leaving the dewatering machine will have moisture levels roughly around 20-30%.

Specifications

| Model #: | Motor Power: | Main Shaft Diameter: | Rotating Speed: | Capacity: |

| HXJ400 | 37KW | 400mm | 1400 RPM | 400 – 800 KG/H |

| HXJ550 | 45KW | 550mm | 1200 RPM | 600 – 1000 KG/H |

| HXJ750 | 55KW | 750mm | 1080 RPM | 1200 – 2000 KG/H |

More Images

Ordering

Our lead time for single pieces of equipment is 30 days from the signing of purchase contract. For custom orders such as complete washing lines, the lead time is between 60 – 90 days. Actual lead times will depend on the project’s complexity as well as our factory’s availability.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.