Product Description

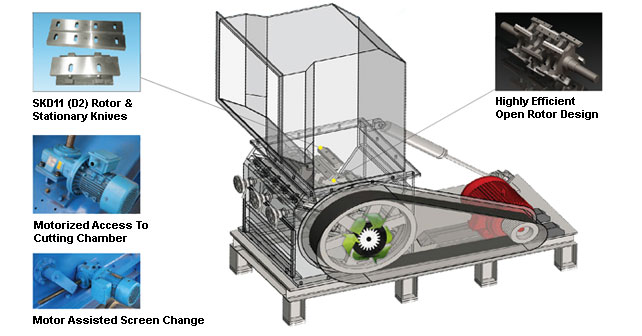

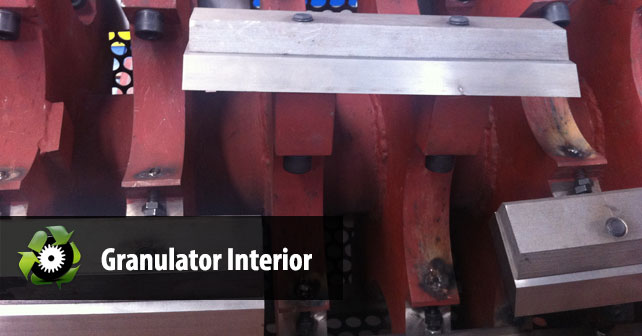

Our PE film washing line uses a wet plastic granulator to cut large pieces of PP / PE film into small, uniform shreds sized between 12-18mm. Our plastic granulator has the unique ability to cut plastic film quickly and efficiently using fast spinning open rotor mounted with heavy-duty knives in a double-scissor cut array. As the plastic film enter the granulator’s cutting chamber, the rotor knives come into contact with stationary knives effective cutting the film in a continuous fashion.

The size of the PE film shreds are controlled by a screen filter with holes that is mounted underneath the cutting chamber. The plastic film is held within the cutting chamber until it reaches the desired size and falls through this screen filter. Usually speaking, our standard screen filter hole size is 15mm.

To ensure reliability and dulling in the most demanding situations, all knives used in our granulator is made from high quality D2 high-carbon, high-chromium steel (equivalent to SDK11 steel). For the sake of usability, all 12 rotor knives and 3 stationary knives can be easily adjusted with hydraulic assisted access to the cutting chamber.

To further benefit from our already robust structural design, our PE film washing lines use a wet granulation process where water is sprayed into the cutting chamber via nozzles. This not only partially cleans the PP/PE films, it also adds a layer of lubrication to reduce friction and heat during long operations. Based on our testing and experimentation, our wet granulators require 2-3 times less knife sharpening compared to dry granulating.

Learn more about plastic granulators.

Specifications

| Model # | Rotor Diameter | Knife Width | Rotating Speed | Approx. Output | Motor Power |

| SWP630-1000 | ⌀630mm | 1000mm | 470 rpm | 1000 kg/h | 55KW |

| SWP630-1200 | ⌀630mm | 1200mm | 470 rpm | 1200 kg/h | 55KW |

| SWP700-1000 | ⌀700mm | 1000mm | 470 rpm | 1500 kg/h | 75KW |

| SWP700-1200 | ⌀700mm | 1200mm | 470 rpm | 1800 kg/h | 75KW |

| SWP800-1000 | ⌀800mm | 1000mm | 470 rpm | 2000 kg/h | 90KW |

| SWP800-1200 | ⌀800mm | 1200mm | 470 rpm | 2500 kg/h | 90KW |

*Larger, more powerful granulators are available based on your request.

More Images

Ordering

Our lead time for single pieces of equipment is 30 days from the signing of purchase contract. For custom orders such as complete washing lines, the lead time is between 60 – 90 days. Actual lead times will depend on the project’s complexity as well as our factory’s availability.

Contact us to discuss pricing and ordering details. Here is a brief summary of our ordering procedures.